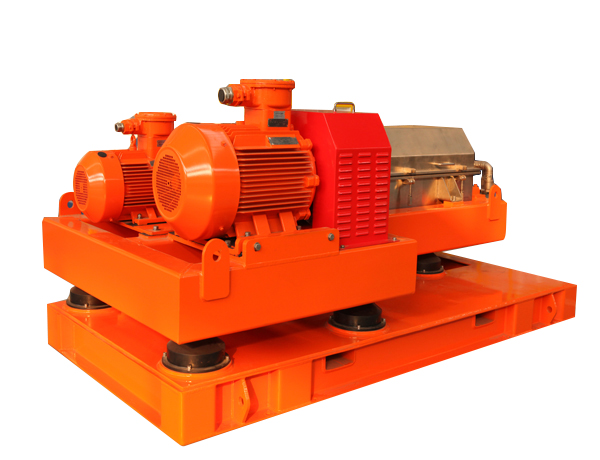

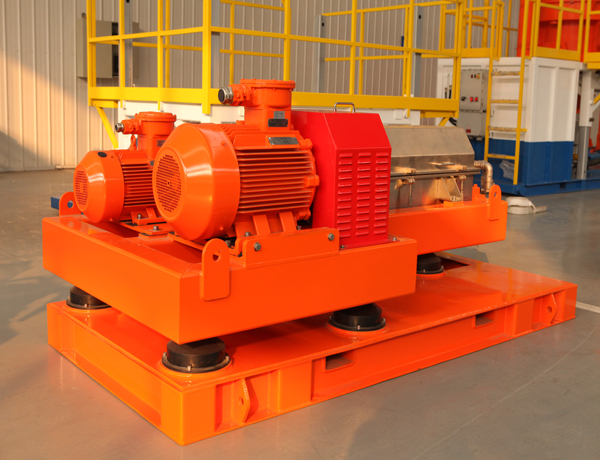

Oily Sludge Centrifuge

The Oily Sludge Decanter separates solid and liquid components in oily sludge and drilling waste through chemical enhancement, heating, and dilution, followed by high-speed separation. The separated oil and water are then recycled separately after final treatment.

Oily Sludge Decanter is specialized for oily sludge treatment, drilling waste separation, tank sludge cleaning. After the oily sludge pretreatment by heating, diluting, chemical enhancement with polymers, the oily sludge will feed to high-speed sludge decanter for first phase solid liquid separation. The solids will be separated to form sludge cake, and the liquid separated mixed with oil and water. In next phase, the oil water will be feed to disc stack separator for final treatment, and can recycle the oil and water separately by oil tank and water tank.

Technical Parameters of KES Separation Oily Sludge Decanter as follows:

|

Model |

KSLW223 |

KSLW363 |

KSLW453 |

KSLW553 |

|

Bowl Diameter |

220mm (9in) |

360mm (14in) |

450mm(18in) |

550mm (22in) |

|

Bowl Length |

670mm(26in) |

1271mm(50in) |

1540mm(61in) |

1800mm (71in) |

|

Operation Capacity |

5m3/h |

30m3/h |

60m3/h |

90m3/h |

|

Max Bowl Speed |

4500rpm |

3900rpm |

3200rpm |

3000rpm |

|

Typical Bowl Speed |

3800rpm |

3200rpm |

0~2800rpm |

0~2500rpm |

|

Max G Force |

2492 |

3063 |

2578 |

2719 |

|

Typical G Force |

1777 |

2062 |

0~1973 |

0~1888 |

|

Separation point |

2~5micron |

2~5micron |

2~5micron |

2~5micron |

|

Differential Speed |

10/20/30 |

0~40 |

0~35 |

0~45 |

|

Gearbox Torque |

500N.M |

3500N.M |

7500N.M |

12000N.M |

|

Gearbox Ratio |

35:1 |

57:1 |

57:1 |

35:1 |

|

Bowl Drive(kw) |

7.5kw |

37kw |

55kw |

90kw |

|

Scroll drive(kw) |

3kw |

11kw |

22kw |

37kw |

|

Weight |

850kg |

3400kg |

4480kg |

5840kg |

|

Dimension (mm) |

2130x790x1115 |

3414x1516x1430 |

3824x1798x1317 |

4293x1978x1381 |

Technical Features of KES Separation Oily Sludge Decanter as follows:

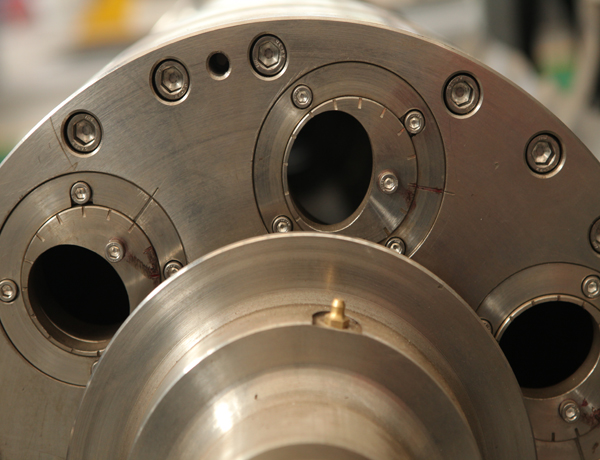

? Main rotation parts made from SS316/SS2205, processed by centrifugal casting technology or mold forging technology

? Screw protection by tungsten carbide alloy tiles or hard facing special technology

? Each part is detected at constant temperature, to ensure the process quality and machining accuracy

? ONLY adopt SKF Sweden or FAG Germany original bearing, to ensure the stable performance and lifetime of bearing

? Equipped with China good brand motors, ABB/Siemens motor for option

? Main electrical components are sourced from China premium brands, SIEMENS, Schneider or ABB for option

? VFD + PLC + HMI Smart control system can achieve much better user experience

? Control system with monitoring device & alarm device, protect decanter from overloading, short circuit and lack of phase

? Decanter centrifuge with DNV2.7-1 Certificate SKID available for offshore drilling activities.