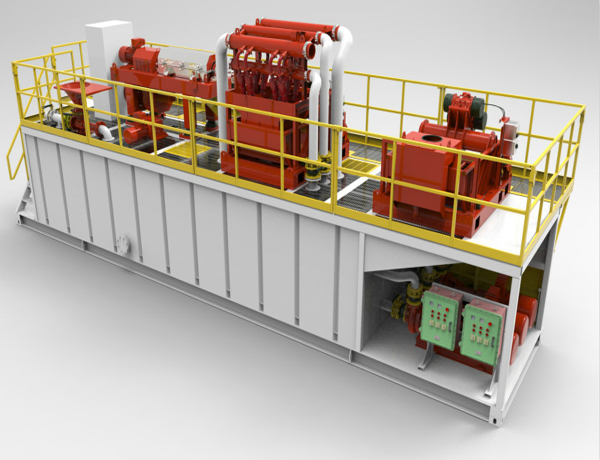

CBM Mud System

KES Separation makes mud recycling systems for HDD Mud Systems, CBM, and Geothermal Drilling Rig. The system includes a shale shaker and desanding mud cleaner that separates large solid particles. Clean drilling mud is pumped back for reuse. We offer both standard and customized mud cleaning systems

Similar to HDD Mud System, CBM and Geothermal Drilling Rig required similar mud cleaning system. KES Separation is a professional manufacturer of mud recycling system. Key equipment includes shale shaker and desanding mud cleaner. After treatment, big size solids particles are separated, clean drilling mud will be pumped back for reuse. After many years’ experiences, we can offer standard mud cleaning system as below table, we can also customize CBM mud system and geothermal drilling mud system according to customer requirement.

KSMS-500A Mud System suitable for 40HC container shipment:

| S/N | Product | Qty | Tank Size (mm) | Weight (T) |

| 1 | Shale Shaker | 1 | 10000x2100x1894 | 13.6 |

| 2 | Mud Cleaner | 1 | ||

| 3 | Centrifugal Pump | 3 | ||

| 4 | Agitator | 1 | ||

| 5 | Mud Hopper | 1 |

KSMS-500B Mud System with ISO container corner, convenient for truck transportation

| S/N | Product | Qty | Tank Size (mm) | Weight (T) |

| 1 | Shale Shaker | 1 | 12192x2438x2088 | 18.1 |

| 2 | Mud Cleaner | 1 | ||

| 3 | Centrifugal Pump | 3 | ||

| 4 | Agitator | 2 | ||

| 5 | Mud Hopper | 1 |

Technical Features of KES Separation CBM Mud System:

Can effectively control drill fluids performance, reduce the drill-jamming accidents and improve pore-forming quality;

Can save bentonite and barite; drastically reduce the waste mud transportation cost;

The effective separation of soil slag by equipment will help to improve pore-forming efficiency;

The slurry closed cycle purification mode and lower slag moisture content reduce the impacts to environment;

Safe and easy operation, simple maintenance, stable and reliable operation.

Reasonable design with compact structure and small footprint